Badcock And Wilcox Boiler Ppt

Embed FALLAS BOILER (BABCOCK AND WILCOX).pdf. A McDermott companyBoilerTubeAnalysisReduceFuture BoilerTubeFailures2Look to the Industry Leader for Comprehensive Tube AssessmentBoiler tube failures continue to be the leading cause of forced outages in fossil-fired boilers.To get your boiler back online and reduce or eliminate future forced outages due to tube failure, it is extremely important to determineand correct the root cause. Experience shows that a comprehensive assessment is the most effective method of determining the root cause of a failure.With more than 125 years experience designing, fabricating, building and servicing boilers, Babcock &Wilcoxis a recognized industry leader and a logical source for tube failure evaluation.

We are Babcock & Wilcox (B&W) - a company founded in 1867 by two friends with an unwavering commitment to reliable and effective innovation. When Stephen Wilcox first avowed that “ there must be a better way ” to safely generate power, he and George Babcock responded with the design for the first inherently safe water-tube boiler, and the. Mar 19, 2018 Babcock and Wilcox Boiler is a horizontal type drum axis, natural circulation, stationary, high pressure, solid fuel-fired water tube boiler. In the year of 1967, it was introduced by George Herman Babcock and Stephen Wilcox. After that Babcock and Wilcox Boiler was named by its inventor as Babcock and Wilcox and till now we are using this name.

A tube failure is usually a symptom of other problems. In addition to evaluating the failure itself, you should investigate all aspects of boiler operation leading to the failure to fully understand the cause. Babcock & Wilcox can assist you in this full-scope investigation with our experienced field service engineershelping to gather all the pertinent information. In many cases, the field investigation can isolate the rootcause that led to the tube failure.World-class Research CenterFor tube sample analyses, B&W can draw on the experience and capabilitiesof our world-class ISOcertified AllianceResearch Center (ARC), Alliance, Ohio.We have metallurgical and chemicalengineering expertise to complementour knowledge of boiler design andoperation. At the ARC, we analyze hundreds of samples every year and provide a full range of failure analysesand material evaluation services.Materials can be examined at magnifications as great as 100,000Xusing our Scanning ElectronMicroscope (SEM). In conjunctionwith the SEM, our electron probemicroanalysis capability allows analysisof chemical elements on the tube surfaces which aids in root cause evaluation.

.Office Remote turns your phone into a smart remote that interacts with Microsoft Office on your PC. The app lets you control Word, Excel, and PowerPoint from across the room, so you can walk around freely during presentations.

.Office Remote turns your phone into a smart remote that interacts with Microsoft Office on your PC. The app lets you control Word, Excel, and PowerPoint from across the room, so you can walk around freely during presentations.

Deposits, whether on the water side or gas side of the tube, also can be analyzed at the ARC using X-ray diffraction and mass spectroscopy techniques.ScanningElectronMicroscopeA chemist tests deposits removedfrom boiler tubesusing X-ray diffraction.Alliance Research Center3Caustic AttackSymptoms:Localized wall loss on the inside diameter (ID) surface of the tube, resulting in increased stress and strain in the tube wall.Causes:Caustic attack occurs when there is excessive deposition on ID tubesurfaces. This leads to diminished cooling water flow in contact with thetube, which in turn causes local under-deposit boiling and concentration of boiler water chemicals. If combined with boiler water chemistry upsets of high pH, it results in a caustic condition which corrosively attacks andbreaks down protective magnetite.Oxygen PittingSymptoms:Aggressive localized corrosion and loss of tube wall, most prevalent near economizer feedwater inlet on operating boilers. Flooded or non-drainable surfaces are most susceptible during outage periods.Causes:Oxygen pitting occurs with the presence of excessive oxygen in boiler water. It can occur during operation as a result of in-leakage of air at pumps, or failure in operation of preboiler water treatment equipment. This also may occur during extended out-of-service periods, such as outagesand storage, if proper procedures are not followed in lay-up.

Non-drainablelocations of boiler circuits, such as superheater loops, sagging horizontalsuperheater and reheater tubes, and supply lines, are especially susceptible.More generalized oxidation of tubes during idle periods is sometimesreferred to asout-of-service corrosion.Wetted surfaces are subject to oxidation as the water reacts with the iron to form iron oxide. When corrosive ash is present, moisture on tube surfaces from condensationor water washing can react with elements in the ash to form acids that lead toa much more aggressive attack on metal surfaces.Hydrogen DamageSymptoms:Intergranular micro-cracking. Loss of ductility or embrittlement of the tube material leading to brittle catastrophic rupture.Causes:Hydrogen damage is most commonly associated with excessive deposition on ID tube surfaces, coupled with a boiler water low pH excursion. Water chemistry is upset, such as what can occur from condenser leaks, particularly with salt water cooling medium, and leads to acidic (low pH) contaminants that can be concentrated in the deposit. Under-deposit corrosion releases atomic hydrogen which migrates into the tube wall metal, reacts with carbon in the steel (decarburization) and causes intergranular separation.Caustic attack at backing ringOxygen pittingon tube IDBrittle failure due to hydrogen damageFinding the Root Cause is CriticalHave you ever repaired a tube leak and put the boiler back in service, only to be forced off-line byanother leak? Red alert 2 deezire 8.0 download windows 7.

Identifying and correcting the root cause is essential. Shown on the following pagesare some of the failure mechanisms found in fossil boiler tubes. When you see tubes in your boilerlike those illustrated, take advantage of B&W’s tube expertise to help you determine and eliminatethe root cause of the problem. Better yet, let us assist you in putting together a complete conditionassessment program to help you find tube problems before failures occur. Acid AttackSymptoms:Corrosive attack of the internal tube metal surfaces, resulting in anirregular pitted or, in extreme cases, a “swiss cheese” appearance of the tube ID.Causes:Acid attack most commonly is associated with poor control of processduring boiler chemical cleanings and/or inadequate post-cleaning passivationof residual acid.Stress CorrosionCracking (SCC)Symptoms:Failures from SCC are characterized by a thick wall, brittle-type crack. May be found at locations of higher external stresses, such as near attachments.Causes:SCC most commonly is associated with austenitic(stainless steel)superheater materials and can lead to either transgranular or intergranularcrack propagation in the tube wall. It occurs where a combination of high-tensile stresses and a corrosive fluid are present.

The damage resultsfrom cracks that propagate from the ID. The source of corrosive fluid may becarryover into the superheater from the steam drum or from contaminationduring boiler acid cleaning if the superheater is not properly protected.Waterside Corrosion FatigueSymptoms:ID initiated, wide transgranular cracks which typically occur adjacent to external attachments.Causes:Tube damage occurs due to the combination of thermal fatigue andcorrosion. Corrosion fatigue is influenced by boiler design, water chemistry,boiler water oxygen content and boiler operation. A combination of theseeffects leads to the breakdown of the protective magnetite on the ID surfaceof the boiler tube.

The loss of this protective scale exposes tube to corrosion.The locations of attachments and external weldments, such as buckstayattachments, seal plates and scallop bars, are most susceptible. The problemis most likely to progress during boiler start-up cycles.Superheater Fireside Ash CorrosionSymptoms:External tube wall loss and increasing tube strain. Tubes commonly have a pock-marked appearance when scale and corrosion products are removed.Causes:Fireside ash corrosion is a function of the ash characteristics of the fuel and boiler design.

It usually is associated with coal firing, but also can occur for certain types of oil firing. Ash characteristics are considered in the boiler design when establishing the size, geometry and materials used in the boiler. Combustion gas and metal temperatures in the convectionpasses are important considerations. Damage occurs when certain coal ashconstituents remain in a molten state on the superheater tube surfaces.

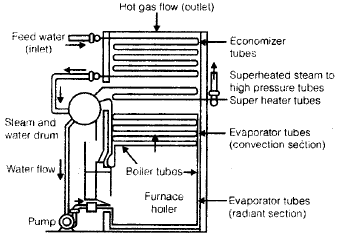

Construction of babcock and wilcox boiler.1.Construction of Babcock and Wilcox BoilerThe Babcock and Wilcox Boiler consists of 1. Steam and water drum (boiler shell) 2. Water tubes 3. Uptake-header and down corner 4.

Super heater 8. Inspection door 10.

DamperSteam and water drum (boiler shell):One half of the drum which is horizontal is filled up with water and steam remains on theother half. It is about 8 meters in length and 2 meter in diameter.Water tubes:Water tubes are placed between the drum and furnace in an inclined position (at an angle of10 to 15 degree) to promote water circulation.